The DuraTech 9013 Industrial Tub Grinder is a powerhouse capable of grinding tree stumps at the rate of 350 cyph (267.59 cumph) with its 950 HP (708.4 kW) CAT C27 Tier II Diesel Engine. Designed and constructed to handle tough jobs, the 9013 combines power with efficiency to get the job done.

Features

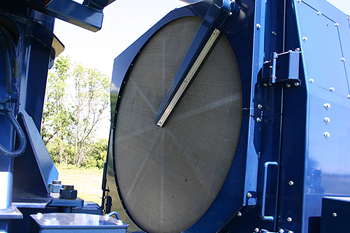

Self-Cleaning Air Intake System

In order to provide constant clean air to the engine and radiator, the 9013FL employs a hydraulically powered self-cleaning air intake system with 3,400 square inches (21,635.4 sq cm) of air passages. The self-cleaning air intake system reduces maintenance, provides easy access to the radiator for servicing, and allows for flexible positioning of the grinder.

Command Console with Optional Remote Control

The 9013FL command console features master engine controls, gauges, and shutoff. Also included on the command console are electric over hydraulic controls for the clutch, governor, and stacking conveyor. The optional 6-function remote controls engine stop, tub rotation, stacking conveyor, and optional tub cover.

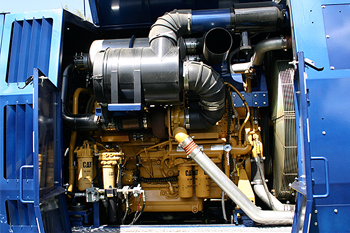

Caterpillar C27 Electronic Diesel Engine with Enclosed Engine Compartment

The 9013FL is powered by a 950 HP (708.4 kW) Caterpillar Electronic diesel engine and is backed up by Caterpillar’s superior service and reliability. The 9013FL is capable of grinding trees at the rate of 350 cu. yds/hr (267.59 cu. m/hr) with the 950 HP engine. The engine is housed in an enclosed engine compartment to protect the engine from debris while reducing noise levels.

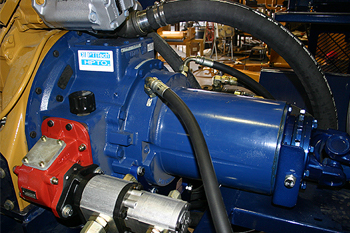

PT-Tech HPTO Oil Cooled Clutch

The 9013FL Industrial Tub Grinder is equipped with a self adjusting PT-Tech HPTO oil cooled clutch. This clutch is microprocessor controlled with a built-in torque limiter and brake that provide superior protection for the engine and drive line.

Single Drive Orbit Motor Drives the Tub

Utilizing a heavy-duty 120H drive chain, a continuous chain sprocket around the tub, an 8” (20.32 cm) heavy-duty tub channel, and dual spring adjustable chain tension, the tub is driven by a single orbit motor. Tub speed is controlled by the electronic governor.

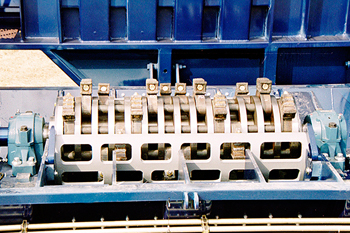

56” Rotor

The 9013FL Industrial Tub Grinder is equipped with a 56” (142.24 cm) rotor mounted on a 7” (17.78 cm) shaft with 4-7/16” (11.27 cm) greasable bearings. The dynamically balanced rotor uses 28 fixed hammers.

36" Wide Belly Belt

36” (91.44 cm) Wide, Impact Resistant Belly Belt carries the finished product to the stacking conveyor.

36” Wide x 26’ Long Oscillating Top Drive Stacking Conveyor

The 36” (91.44 cm) wide by 26’ (7.92 m) long stacking conveyor allows the operator to load material into a truck or onto an existing pile. Additionally, the stacking conveyor swings 25 degrees from side-to-side. An optional magnetic roller and aluminum chute remove ferrous metal from the finished product.

8000 Series Continuous Rotating Grapple Loader

The 8000 series continuous rotating grapple loader on the 9013FL Industrial Tub Grinder features joystick operator controls, 27’ (7.62 m) boom length, 5-prong wide reach grapple, secondary controls gauges in the cab, and the ability to raise the cab 4’ (1.22m) and rotate it for unobstructed view and operator comfort.

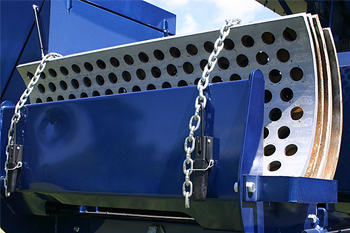

Screen Storage Back

The 9013FL Industrial Tub Grinder is equipped with a screen storage rack for supplemental or spare screens.

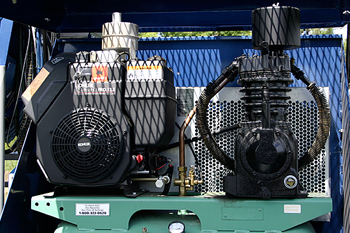

Optional Air Compressor

The 9013FL Industrial Tub Grinder can be equipped with an optional 12 HP air compressor with vandal protection and 50' of 1/2" hose with storage reel. Additionally, a 3/4" air impact with two sockets and extension is available.

Find a DuraTech Dealer

Standard Options

- HPTO oil cooled clutch

- Single orbit motor tub drive through 120H chain

- 36” wide stacking and belly belts

- Self-cleaning air intake system

Optional Features

- Remote control

- Magnetic roller complete with aluminum deflector chute

- Screen sizes

- Lockable steel toolbox

- Tub cover

Specifications

| WEIGHT | |

|---|---|

| Weight w/Fifth Wheel Hitch | 69,800 lbs. (31,668.8 kg) |

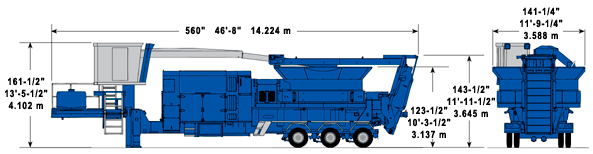

| TRANSPORT DIMENSIONS | |

| Transport Width | 11 ft. 9-1/4 in. (3.58 m) |

| Transport Height without Loader | 11 ft. 11-1/2in. (3.65 m) |

| Transport Length | 46 ft. 8 in. (14.22 m) |

| CHASIS FEATURES | |

| Engine | CAT C27 950 (708.4 kw) HP |

| Axle | (3) - 22,500 lbs. (10,205.82 kg) |

| Electrical | 24 Volt Machine |

| Tires | 255/70R X 22.5 |

| Weight on Hitch Pin w/o Loader | 13,800 lbs. (6,259.6 kg) |

| Fuel Capacity | 300 Gallons (1,135 Liters) |

| Hydraulic Oil Capacity | 110 Gallons (416.4 Liters) |

| Lights | Clearance, Directional |

| TUB | |

| Tub Width | 12 ft. 6 in. (3.81 m) |

| Depth | 56 in. (142.24 cm) |

| Tub Diameter at Base | 10 ft. (3.05 m) |

| Tub Wall | 3/8 in. (.953 cm) Thick |

| Tub Floor | 1/2 in. (1.27cm) Thick AR Steel |

| Tub Drive | 120H Chain, Single Drive Hydraulic Motor |

| Service Access | 90° Tilting Tub |

| Tub Speed Sensor | Electronic Self Governing |

| CONVEYORS | |

| Stacking Conveyor | 26 ft. Long (7.92 m) x 36 in. (91.44 cm) Wide |

| Belly Conveyor | 36 in. (91.44 cm) Wide Impact Resistant |

| HAMMERMILL | |

| Hammers | 20 Fixed Single Bolt |

| Rotor - Shaft Diameter | 7 in. (17.78 cm) Alloy Steel |

| Rotor Length | 56 in. (142.24 cm.) |

| Rotor Plates | 18 in. (45.72 cm) Diameter x 1-1/2 in. (3.81 cm) Thick |

| Feed Opening | 58-1/2 in. x 26-1/2 in. (148.59 cm x 67.31 cm) |

| Screen Area | 3,140 Square Inches (20,258 sq. cm) |

| Hammer Rods | (8) - 2 in. Diameter (5.08 cm) |

| Bearings | 4-7/16 in. (11.27 cm) Greasable Bearing |

| Hammermill Drive | Direct Drive through HPTO Oil Cooled Clutch |