Made to grind or regrind, the DuraTech 3309 series of Industrial Tub Grinders are the most economical grinders on the market.

With a CAT C9 325 HP (242.4 kW) Tier III diesel engine, a self-adjusting HPTO microprocessor-controlled clutch, and enclosed engine compartment with a self-cleaning air intake system, it’s efficient and affordable. Plus, it’s available with a pintle or fifth wheel hitch and as a track powered unit for those hard to get to grinding sites. The DuraTech 3309 Industrial Tub Grinders are built to grind and built to last.

Features

Rotary Self-Cleaning Screen with Enclosed Engine Compartment

The self-cleaning screen combined with the enclosed engine compartment reduces maintenance and noise, and provides for flexible positioning of the grinder. The door on the screener and the three doors per side on the engine compartment provide easy access to the radiator, oil coolers, and engine for servicing.

Command Console with Remote Control

The Model 3309 Track Command Console features master engine controls, gauges, and shutoff. Also included on the command console are electric over hydraulic controls for the clutch, governor, and stacking conveyor. The optional 6-function remote controls engine stop, tub rotation, stacking conveyor, and optional tub cover.

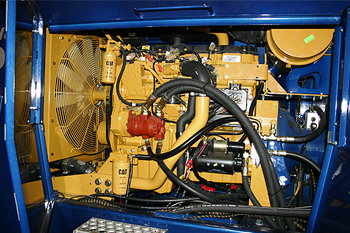

325 HP C9 Caterpillar Electronic Diesel Engine with Enclosed Engine Compartment

The 3309 Track is powered by a 325 HP (242.4 kW) C9 Caterpillar Electronic diesel engine that has the lowest decibel reading in its class, and is backed up by Caterpillar’s superior service and reliability. The engine is housed in an enclosed engine compartment to protect the engine from debris while further reducing noise levels.

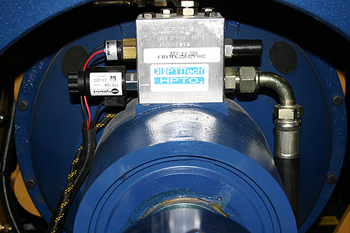

PT-Tech HPTO-12 Clutch

The Model 3309 Track industrial Tub Grinder is equipped with a self adjusting PT-Tech HPTO-12 clutch. This clutch is microprocessor-controlled with a built-in torque limiter and brake that provide superior protection for the engine and drive line.

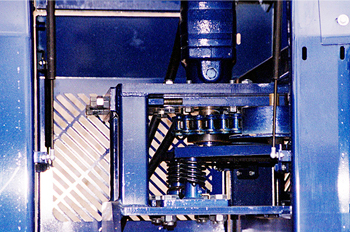

Single Drive Orbit Motor Drives the Tub

Utilizing a heavy-duty 120H drive chain, a continuous chain sprocket around the tub, and dual spring adjustable chain tension, the tub is driven by a single orbit motor. Tub speed is controlled by the electronic governor.

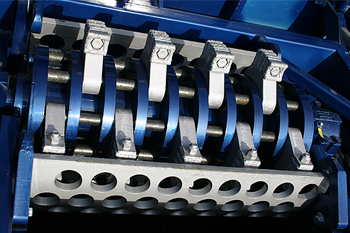

40” Rotor

The 3309 Track Industrial Tub Grinder is equipped with a 40” (101.43 cm) rotor mounted on a 4-1/2” (11.43 cm) shaft with 3-1/2” (8.89 cm) greasable bearings. The dynamically balanced rotor may be used with either 20 fixed hammers or 36 swinging hammers.

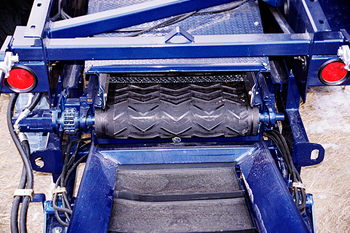

30" Wide Belly Belt

The 30" wide impact-resistant belly belt carries the finished product to the stacking conveyor.

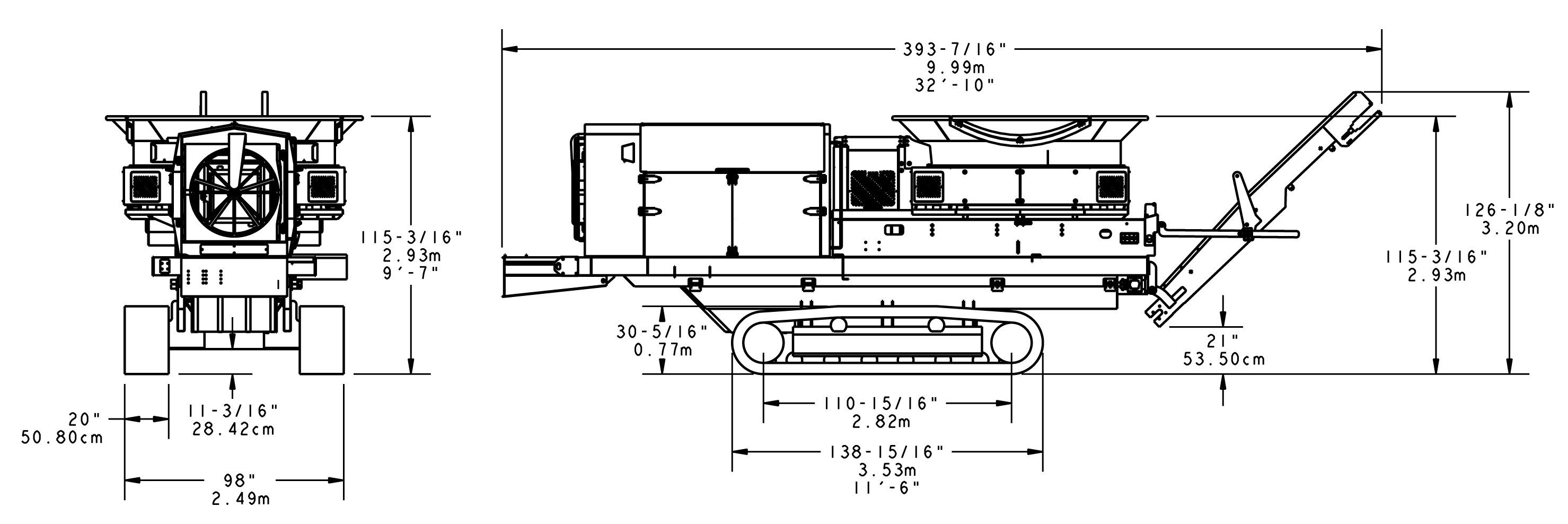

24” Wide x 11’ 6” Long Top Drive Compact Stacking Conveyor

The 24” (60.96 cm) wide by 11’ 6” (3.5 m) long top drive compact stacking conveyor allows the operator to load material into a truck or onto an existing pile. An optional magnetic roller and aluminum chute remove ferrous metal from the finished product.

Caterpillar Track System

The 3309 Track Industrial Tub Grinder is equipped with a 312 CAT Track with 500mm shoes.

Find a DuraTech Dealer

Standard Options

- Built in torque limiter and brake

- 40” rotor mounted on 4 1/2" shaft with 3 1/2" greasable bearings

- 325 HP C9 Caterpillar Electronic Diesel Engine

- Self-cleaning air intake system

- 24” wide top drive 21’ stacking conveyor

Optional Features

- Fixed or swing hammers

- Magnetic roller complete with aluminum deflector chute discharge conveyor drive roller

- Remote control

- Tub cover

Specifications

| WEIGHT | |

|---|---|

| Total | 30,000 lbs. (13,608 kg) |

| TRANSPORT DIMENSIONS | |

| Transport Width | 8 ft. 6 in. (2.59 m) |

| Transport Length | 27 ft. 5 in. (8.36 m) |

| Transport Height w/ Tub Cover | 129.85 in. (329.82 cm) |

| ENGINE AND TRANSMISSION | |

| Engine | Caterpillar 325 HP C9 Electronic Diesel |

| Clutch | PT Tech HPTO-12 |

| Governor | Electro-Hydraulic Load Sensing |

| Safety Switches | Safety Shutdown |

| CHASIS FEATURES | |

| Electrical | 24 volt machine |

| Fuel Capacity | 100 Gallons (378.5 Liters) |

| Hydraulic Oil Capacity | 50 Gallons (189.3 Liters) |

| TUB | |

| Tub Width | 9 ft. 6-3/8 in. (2.91 m) at Flare |

| Depth | 3 ft. 4 in. (1.02 m) |

| Tub Diameter at Base | 7 ft. 6 in. (2.27 m) |

| Tub Wall | 3/16 in. (.476 cm) Thick |

| Tub Floor | 1/4 in.(.635 cm) Thick |

| Tub Drive | Hydraulic Orbit Motor |

| Tub Speed Sensor | Electronic Self Governing |

| CONVEYORS | |

| Stacking Conveyor | 11 ft. 6 in. (3.5 m) Long Top Drive X 24 in. (60.96 cm) Wide X 8" (20.3 cm) Depth |

| Belly Conveyor | 30 in. (76.2 cm) Wide /w a V Cleat |

| HAMMERMILL | |

| Hammers | 20 Fixed Single Bolt Hammers, or 36 Swing Hammers |

| Length | 40 in. (101.6 cm) |

| Cylinder Shaft | 4-1/2 in. (11.43 cm) Stress Proof Steel |

| Cylinder Plates | 16 in. (40.64 cm) Diameter X 1-1/2 in. (3.81cm) Thick |

| Hammermill Opening | 41 in. (104.14 cm) X 25 in. (63.5 cm) |

| Screens | 1 in. (2.54 cm) Thick Split Screens |

| Hammer Rods | 1-1/2 in. (3.81 cm) Diameter |

| Bearings | 3-1/2 in. (8.89 cm) Pillow Block Bearings |

| Hammermill Drive | Direct Drive Torque Limiter |