If you want a horizontal grinder that will give you the maximum return on your investment, this is the one.

This heavy-duty mid-sized grinder is now available on a CAT 320 L Track System. It is available with your choice of CAT Tier III engines to meet your grinding needs.

Features

48” Wide x 30’ Long Oscillating Stacking Conveyor

The 48” (121.92 cm) wide by 30’ (9.14 m) long stacking conveyor allows the operator to load material into a truck or onto an existing pile. Additionally, the stacking conveyor swings 40 degrees from side-to-side. An optional magnetic roller and aluminum chute remove ferrous metal from the finished product.

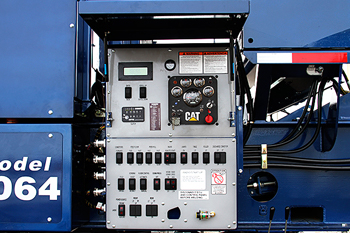

Command Console with Optional Remote Control

The 8564 command console features master engine controls, gauges, and shutoff. Also included on the command console are electric over hydraulic controls for the clutch, governor, and stacking conveyor. The optional 19-function remote control allows the operator to have complete control of the grinder while operating support equipment.

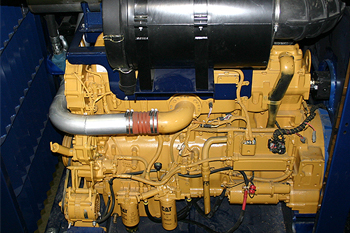

1050 HP C27 Caterpillar Electronic Diesel Engine with Enclosed Engine Compartment

The 8564 is powered by a 1050 HP (782.9 kW) C27 Caterpillar Electronic diesel engine that is backed up by Caterpillar’s superior service and reliability. The engine is housed in an enclosed engine compartment to protect the engine from debris and reduce noise levels.

Rotary Self-Cleaning Screen

In order to provide constant clean air to the engine and radiator, the 8564 employs a rotary self-cleaning screen. The rotary self-cleaning screen reduces maintenance, provides easy access to the radiator for servicing, and allows for flexible positioning of the grinder.

PT-Tech HPTO-15 Wet Clutch

The 8564 Horizontal Grinder is equipped with a self-adjusting PT-Tech HPTO-15 wet clutch. This clutch is microprocessor-controlled with a built-in torque limiter and brake that provide superior protection for the engine and drive line.

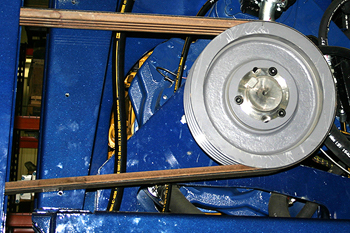

10 Groove Belt Drive

The 10 groove belt drive connects the wet clutch to the hammermill.

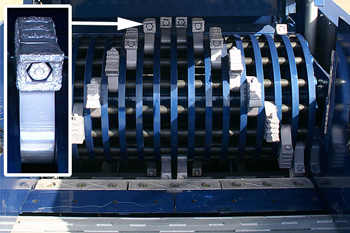

64” Hammermill

The 8564 Horizontal Grinder is equipped with a 64” (162.56 cm), 12,100 pound (5488.47 kg) hammermill with 24 hammers.

Self-Governing Floor Apron and Feed Roller

The hammermill is fed by a self-governing floor apron and feed foller through a 60” (152.4 cm) wide by 40” (101.6 cm) high feed opening. The high capacity 315 cu. ft. (8.91 cu m) hopper will handle the largest trees and stumps.

Four Hydraulic Stabilizer Legs

The 8564 is equipped with four hydraulic stabilizer legs to provide a rock-steady platform while grinding.

Find a DuraTech Dealer

Standard Options

- Self-cleaning air intake system

- Self-governing apron and feed roller

- 40 degree oscillating stacking conveyor pivots

- 10 groove belt drive system

- 12,100 lb hammermill

- HPTO wet clutch

Optional Features

- Magnetic discharge roller

- Remote control

- Engine powered air compressor with hose reel and air hose

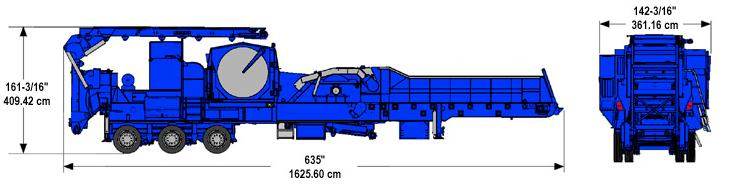

Specifications

| WEIGHT / AXLE / SUSPENSION | |

|---|---|

| Spacing | 57-1/2 in. (1.46 m) |

| 5th Wheel Weight | 33,750 lbs (15,308.74 kg) |

| Total Axle Weight | 57,750 lbs (26,195 kg) |

| Total Weight | 91,500 lbs (41,503.7 kg) |

| MACHINE DIMENSIONS | |

| Transport Width | 11" 10" (2.59 m) |

| Transport Height | 13" 5" (4.09 m) |

| Transport Length | 53' (15.18 m) |

| DRIVE SYSTEM | |

| Engine | Caterpillar C-27 1050 HP (782.9 kW) Diesel Engine |

| Clutch | HPTO 15 TD Wet Clutch |

| Fuel Capacity | 380 gal (1,440 L) |

| Fuel Consumption | 45.7 gal/hr (179.8 L/hr) |

| Hydraulic Oil Capacity | 145 gal (548.9 L) |

| Rotor Drive | 10 Groove 8V |

| FEED SYSTEM | |

| Hopper Capacity | 315 cu. ft. (8.91 cu m) |

| Hopper Width | 61-1/2" (156.2 cm) Bottom, 74" (187.7 cm) Top |

| Hopper Length: | 248" (629.9 cm) Door Up 300" (762 cm) Door Down |

| Hopper Depth | 35" (88.9 cm) |

| Feed Opening | 61-1/2" X 40" (156.2 cm x 106.6 cm) |

| Feed Height | 96" (234.8 cm) |

| GOVERNING SYSTEM | |

| Electric (PLC) | Programmable Logic Controller |

| Hydraulic Drives | Two Load Sensing Pumps |

| The PLC (Programmable Logic Controller) regulates feed rate based on rotor speed. Feed rate is proportional to rotor speed. Maximum feed rate is adjustable. Hammermill weight consists of shaft, hammer rods, bits, hardware, and tool holders. | |

| HAMMERMILL | |

| Rotor Shaft Size | 5-7/16" (13.81 cm) |

| Rotor Width | 64" (162.6 cm) |

| Rotor Speed | 1,125 RPM |

| Tip Swing Diameter | 50-3/4" (126.9 cm) |

| Number of Tips | 24 |

| Cylinder Mid Plates | 1-1/2" (3.81 cm) Thick x 39" (99.06 cm) Diameter |

| Cylinder End Plates | 1-1/2" (3.81 cm) Thick. x 40" (101.06 cm) Diameter T-1 Material |

| Weight | 12,100 lbs (5488.47 kg) |

| Hammer Rod Size | 3-1/4" (8.26 cm) |

| FEED ROTOR | |

| Rotor Diameter | 42" (106.9 cm) |

| Drive | Dual Orbit Motor / Double Reduction Gearboxes |

| SCREENS | |

| Screen Area | 4,340 sq. in. (27,99.944 sq cm) |

| Thickness | 1" (2.54 cm) |

| Hole Sizes | Available in a variety of sizes |

| BELLY CONVEYOR | |

| Length | 28-1/2' (8.69 m) |

| Width | 54" (137.2 cm) |

| STACKING CONVEYOR | |

| Length | 30.5' (9.3 m) |

| Width | 48" (121.9 cm) |

| Oscillating | 40 Degree side-to-side |

| Stacking Height | 22' (6.71 m) @ 30 Degree Incline |

| OPTIONS | |

| Air Compressor | Available |

| Magnetic Roller | Available |