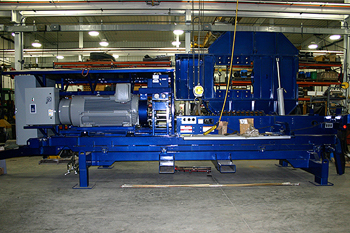

DuraTech’s 3309 Tub grinders just became stationary!

It is now available with electric motor drives. A 400 HP soft start main drive motor as well as a 75 HP motor to power the hydraulic system are available in various voltages to fit your power grid specifications. These electric motors provide steady power with no emissions, little maintenance, and reduced noise levels

Features

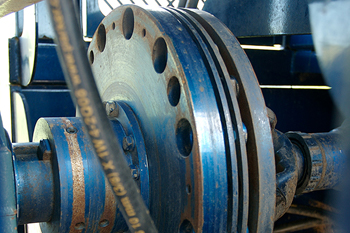

Proven PT-Tech Torque Limiter

The 3309 Electric Industrial Tub Grinder is equipped with the proven self-adjusting PT-Tech torque limiter that protects the motor and hammermill from overloads and costly repairs.

Super Single Tires on Tandem Axles

The 3309 Electric mobile unit comes equipped with 25,000 lbs (11,339kg) tandem axles, a pintle hitch, (4) 445/50 R 22.5 super single tires, and air or optional 24 Volt electric brakes. The mobile unit is also equipped with clearance, directional, and brake lights.

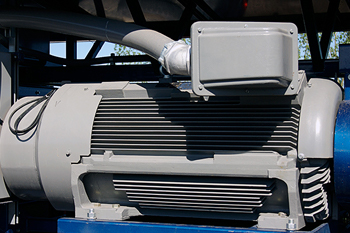

Energy Efficient 75 HP Electric Motor Runs the Hydraulics

The 3309 Electric utilizes either an energy efficient 75 HP / 380 Volt / 50 Hz or a 75 HP / 460 Volt / 60 Hz motor to run all the grinder hydraulics including the tub drive.

Heavy Duty High Performance 40” Rotor

The 3309 Electric Industrial Tub Grinder is equipped with a 40” (101.6 cm) rotor mounted on a 4-1/2” (11.43 cm) stress proof steel shaft with 3-1/2” (8.89 cm) pillow block bearings. The dynamically balanced rotor may be used with either 20 fixed hammers or 40 swinging hammers.

Soft Start for the 75 HP Motor

The Model 3309 Electric industrial tub grinder utilizes a soft start for the 75 HP electric hydraulic drive motor.

High Power & Low Maintenance Provided By the 400 HP Electric Main Drive Motor

The 3309 Electric utilizes either a high power, low maintenance 400 HP / 380 Volt / 50 Hz or a 400 HP / 460 Volt / 60 Hz motor to run the main drive.

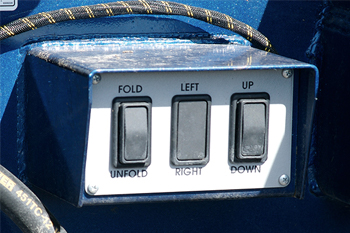

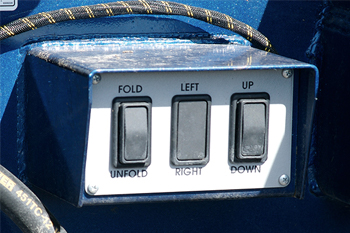

Convenient Secondary Rear Conveyor Controls

Secondary conveyor controls located at the base of the conveyor on the left-hand side of the machine provide operating convenience and flexibility.

Energy Saving Soft Start for the 400 HP Motor

The 3309 Electric Industrial Tub Grinder utilizes an energy saving soft start for the 400 HP main drive electric motor.

Conveniently Located Command Console with Optional Remote Control

The 3309 Electric Command Console features master motor controls for both the 75 HP and 400 HP electric motors, gauges, and shutoff. Also included on the command console are electric over hydraulic controls for the optional tub cover, tub tilt, governor, and stacking conveyor. The optional 6 function remote controls engine stop, tub rotation, stacking conveyor, and optional tub cover.

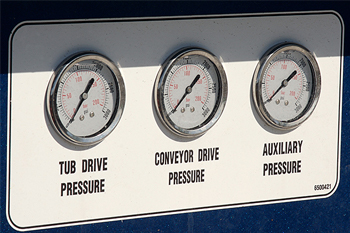

Easy-To-Read Hydraulic Gauges

Large, easy-to-read hydraulic gauges are located on the left side at the center of the machine as viewed when facing the hitch from the rear of the machine. Gauges show Tub Drive Pressure, Conveyor Drive Pressure, and Auxiliary Hydraulic Pressure.

Convenient Secondary Rear Conveyor Controls

The 24” (60.96 cm) side by 21’ 6” long top drive stacking conveyor allows the operator to load material into a truck or onto a pile up to 16’ (4.88 m) high. The optional magnetic roller and aluminum chute remove ferrous metal from the finished product to provide a clean end product.

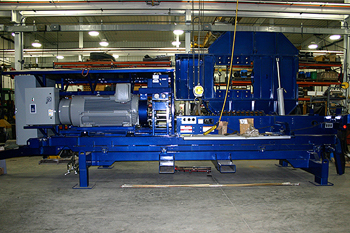

Optional Skid Mount Available for Permanent Installation

DuraTech offers you the option of having the 3309 Electric in a mobile unit configuration if you have more than one grinding location that you need to move the unit between, or the skid mounted 3309 Electric is available for a permanent location.

Find a DuraTech Dealer

Standard Options

-

Self-adjusting PT-Tech torque limiter

-

Super single tires on tandem axles

-

75 HP electric motor

-

40” rotor mounted on a 4-1/2” stress proof steel shaft

-

Soft start for the 75 HP motor

Optional Features

Machine Configuration Options (Must choose one)

Skid Unit

Mobile Unit

Hammer Options: (Must choose one)

(40) Swing Hammers

(20) Fixed Hammers

Screen Options: (Must choose one)

Screen 1" Hole 1/2" Thick Hardox w/ Doubler

Screen 1 1/2" Hole 1/2" Thick Hardox w/ Doubler

Screen 2" Hole 1" Thick

Screen 3" Hole 1" Thick

Screen 4" Hole 1" Thick

Screen 4 3/4" x 7" Hole 1" Thick

Screen 6" x 9" Hole 1" Thick

Hitch Options: (Must choose one)

Pintle Hitch with Air Brakes

Pintle Hitch with optional Electric Brakes

Discharge Conveyor Drive Roller: (Must choose one)

Top Drive Roller

Magnetic Roller 21' 6" Conveyor

Remote Control Option: (Must choose one)

No Remote Control

6 Function Tub: Start, Stop, Rev Cnvyr: Up, Down Eng: Kill

6 Function plus Cover: Raise, Lower

Tub Cover

An operational characteristic of all grinders is that objects may be thrown out of the tub. Tub covers reduce the risk of potential injury or property damage from thrown objects. Proper use of the tub cover provides the operator with a means to help control the area over which thrown objects may fall. Combined with a decrease in the percentage of objects thrown from the tub, the tub cover is an effective means of reducing risk to personnel and property.

Specifications

| GENERAL SPECIFICATIONS | |

|---|---|

| Motor-Main Drive | 400hp/380V/60HZ- South Korea Only |

| Motor-Hydraulic Drive | 75hp/380V/60HZ- South Korea Only |

| Motor-Main Drive | 400hp/380V/50HZ |

| Motor-Hydraulic Drive | 75hp/380V/50HZ |

| Motor-Main Drive | 400hp/4600V/60HZ |

| Motor-Hydraulic Drive | 75hp/460V/60HZ |

| Hydraulic Oil Capacity | 50 Gallons (189.3 Liters) |

| Tub Governor | Electro-Hydraulic Sensing |

| Tub Speed Sensor | Magnetic Sensor |

| Tub Width | 9’ 6-3/8” (2.91 m) at Flare |

| Tub Depth | 40” (1.02 m) |

| Tub Diameter at Base | 7’ 6” (2.27 m) |

| Tub Wall | 3/16” (.476 cm) Thick |

| Tub Floor | 1/4” (.635 cm) Thick |

| Tub Drive | Hydraulic Orbit Motor |

| Safety Switches | Tub Tilt in relationship to Hammermill operation |

| Belly Conveyor | 30” (76.2 cm) Wide |

| Discharge Conveyor | 21’ 6” (6.55 m) Top Drive L- 24” (60.96 cm) Wide |

| Hammermill Opening | 41” x 25” (104.14 cm x 63.5 cm) |

| Hammermill Drive | Belt and pully through Torque Limiter |

| Rotor Length | 40” (101.6 cm) |

| Rotor Plates | 16” (40.64 cm) in Diameter 1” (2.54 cm) Thick |

| Rotor - Shaft Diameter | 4-1/2” (11.43 cm) Stress Proof Steel |

| Bearings | 3-1/2” (8.89 cm) Pillow Block Bearings |

| Hammer Rods | 1-1/2” (3.43 cm) Diameter |

| Hammers | 20 Fixed Single Bolt, or 40 swinging hammers |

| Screens | 1” (2.54 cm) Thick Split Screens |

| Screen area | 2,240 Sq in (14,451.6 sq cm) |

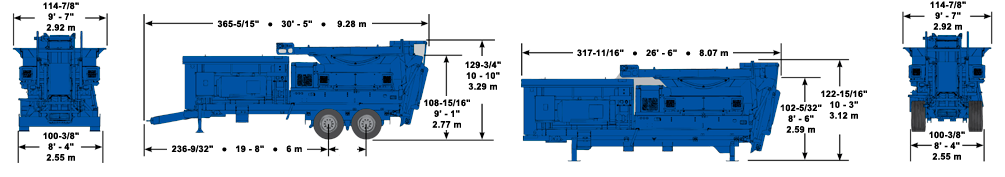

| SKID UNIT-SPECIFICATIONS | |

| Weight: | With 460 volt motor 29,020 lbs. (1,163.25 kg) approximate With 380 volt motor 30,120 lbs. (13,662.2 kg) approximate |

| Transport Width | 8’4” (2.55 m) |

| Length | 26’6” (8.07 m) |

| Height | 10’10” (3.29 m)/td> |

| MOBILE UNIT-SPECIFICATIONS | |

| Width: | With 460 volt motor 30,520 lbs. (13,843.64 kg) With 380 volt motor 31,620 lbs. (14,434 kg) |

| Transport Width | 8’4” (2.55 m) |

| Length | 30’5” ( 9.28 m) |

| Height | 10’10” (3.29 m) |

| Axle | Tandem axles, 25,000 lbs (11,339.01 kg) |

| Tires | (4) 445/50 R 22.5 Super Single |

| Tongue Weight | 6,340 lbs (2,876 kg) |

| Brakes | Air or Optional 24 Volt Electric |

| Electrical-trailer | 12 Volt / 24 Volt |

| Lights | Clearance, Directional and Brake |